Tips for cleaning solar systems

Module cleaning: How to maximize the yield of your PV system

Solar parks and rooftop systems are exposed to the weather around the clock. Over time, leaves, dust, pollen, and bird droppings accumulate on the PV modules. The soiling can reduce the performance of the system by up to a quarter. It is therefore important to clean the photovoltaic modules occasionally. We will show you what is important when cleaning the solar system.

When is pv cleaning necessary?

Module cleaning depends on the location

Additional revenue should exceed cleaning costs

When is photovoltaic cleaning necessary?

The good news first: rain and snow usually wash away light soiling reliably. Problems arise when there is no rain for a long time. Or if the angle of inclination of the modules is too low: then the water cannot run off optimally, so that dirt remains on the modules. Self-cleaning also reaches its limits when dirt is very persistent or in hard-to-reach places, such as the edges of the module. In these cases, professional cleaning is required.

The soiling should be removed immediately because it has the same effect as shading: the solar system can absorb little or no sunlight at these points and generate less solar power. 10 to 20 per cent of the maximum output can get lost this way.

However, solid deposits such as bird droppings are also a safety risk: they can cause the solar installation to overheat and cause a fire. This is known as the "hot-spot effect".

Module cleaning required more frequently depending on location

How often professional cleaning of the solar system is necessary depends primarily on the location: In the neighbourhood of farms, for example, persistent soiling occurs more frequently than in the city. In addition, the exhaust gases from traffic on busy roads cause more deposits on the photovoltaic system. In both cases, more frequent inspections are necessary.

The same applies to regions where there is little rainfall. Here, the precipitation is generally not sufficient for the photovoltaic modules to clean themselves. A nearby building site can also cause a lot of additional dirt, meaning that owners or professionals often have to tackle their solar installation themselves.

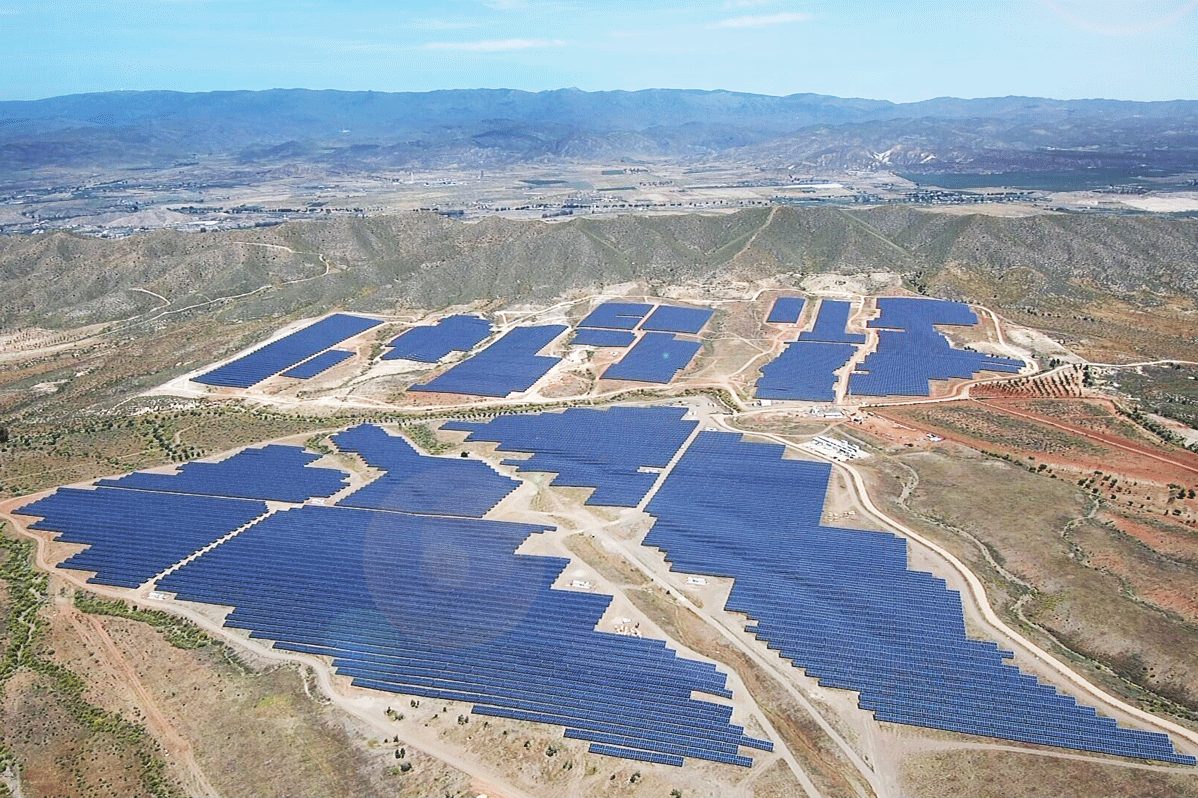

In dry regions such as the Tabernas Desert, there is not enough rainfall for self-cleaning. Here, the SENS service team keeps the photovoltaic system clean and thus ensures consistently high yields.

PV systems in the vicinity of farms generally need to be cleaned more frequently, as dirt is regularly generated here due to dust from vehicles, feed, etc.

Additional revenue should exceed cleaning costs

How often a PV system should be cleaned is primarily an economic decision in addition to the conditions at the respective location: Module cleaning by a special-ized company such as SENS is always worthwhile if the costs are lower than the yield gain from clean modules.

If air pollution is low, it is usually sufficient to have the system professionally cleaned every three to five years. Annual photovoltaic cleaning is only necessary in heavily polluted areas.

Clean modules yourself or commission a specialist company?

System operators are well advised to always leave photovoltaic cleaning in the hands of experts. This is because there is a high risk of damaging the sensitive solar modules with unsuitable cleaning equipment, brushes or excessively harsh cleaning agents. This is because of the special glass that is coated with an invisible, ultra-fine anti-reflective layer. The warranty is also at risk if the manufacturer's cleaning instructions are not followed exactly. In the case of roof-mounted systems, there is also the risk of injury if the system is not adequately secured.

Cleaning the solar system at a specialised company can also be easily combined with maintenance. This saves costs, as the experts can immediately check the system for technical defects and faults during module cleaning and repair them if necessary.

Practical tips for cleaning a solar power system

If you want to clean your photovoltaic system yourself, you should consider the following points:

- Rainwater is best suited for cleaning solar panels. Tap water can lead to limescale deposits and streaks!

- Remove loose dirt beforehand with a soft broom that does not scratch the glass cover of the PV modules.

- Use gentle cleaning agents! Environmentally friendly household or glass cleaners, for example, are well suited. Never use a high-pressure cleaner!

- Do not walk on the system during cleaning as this can cause cracks in the modules. It is better to use a telescopic pole.

- Only clean the modules when they are cold; a cool, cloudy day is ideal.

- Take care with the electrical connections: Contact with water can cause short circuits.

Professional cleaning of solar parks and large PV rooftop systems

If you want to leave the cleaning of photovoltaic systems to professionals, SENS is the right partner for you. Whether open-space photovoltaic systems or rooftop PV systems: we have years of experience in the field of photovoltaic services. PV cleaning is naturally part of this, as green cutting, condition checks and repairing damage. We ensure the highest possible performance of your system through customized services.

Find out more about our cleaning service for PV systems here.

Pictures: SENS´partner

Update: 24 January 2024